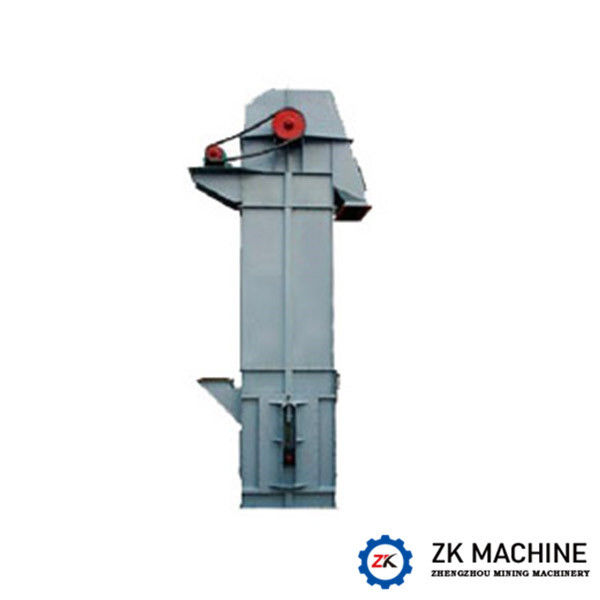

Bucket Elevator Operation Precautions and Maintenance

Bucket Elevator Introduction:

The bucket elevator is maintained and managed by designated personnel and the keys of the power switch box are to be administered by designated personnel. Bucket elevator should drive at no load. Therefore, before each stop should exhaust all the material inside the hopper, and then stop.

Bucket elevator operation precautions:

1. The bucket elevator by the designated personnel for maintenance and management, the power switch box key by the designated personnel management.

2. The bucket elevator must have hoist limiter and travel limiter, the limiter should be pulleys in the promotion to the reel or pulley 300mm ago can automatically stop.

3. Bucket elevator should have the maximum load signs, lifting, landing weight overload allowed (1T).

4. After power transmission, check winch limiter, travel limiter, interlock switch and other safety devices, action sensitive and reliable, and test hanging.

5. Lifting, landing before the bell alarm, before driving.

6. Bucket elevator have no right to allow people up and down.

7. After finishing work, bucket elevator lifting plate should be landing, and then cut off the power, shut down the fence up and down the door.

8. Keep the environment around the bucket elevator health.

Bucket elevator maintenance:

1. Bucket elevator should drive at no load. Therefore, before each stop should exhaust all the material inside the hopper, and then stop.

2. Cannot be reversed, reversal chain derailment may occur, to exclude derailment trouble is troublesome.

3. Even feeding, prohibit suddenly increase the feeding amount. Feeding volume cannot exceed the conveying capacity of the bucket elevator. Otherwise easily lead to the bottom of the material accumulation serious "stuffy car" accident.

4. Timely replenishment of oil.

5. The chain and hopper serious wear or damage should be promptly replaced.

Specifications:

| Model |

Bucket

Type

|

Capacity

(m³/h)

|

Bucket Width

(mm)

|

Bucket Pitch

(mm)

|

Belt Width

(m/s)

|

Bucket Running Speed

(m/s)

|

Max Size of Material (mm) |

Elevating Height

(m)

|

| TD160 |

Q |

S |

5~12 |

160 |

400 |

200 |

1.4 |

25 |

≤20 |

| TD250 |

Q |

S |

20~35 |

250 |

400 |

300 |

1.6 |

35 |

≤30 |

| TD315 |

Q |

S |

25~40 |

315 |

500 |

400 |

1.6 |

45 |

≤30 |

| TD400 |

Q |

S |

35~66 |

400 |

500 |

450 |

1.6 |

55 |

≤30 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!