Medium Scale Double Shaft Mixer Used In Building Materials, Metallurgy, Machinery

Double Shaft Mixer Introduction:

The double-shaft mixer is a device that uses the synchronous rotation of a pair of spiral shafts with mixing blades to spray, humidify and agitate powder materials while conveying them. Double Shaft Mixer can be used for mixing and crushing clay materials in the ceramsite industry; materials such as fly ash and aggregates, additives, etc. are uniformly mixed and mixed. This type of Double Shaft Mixer has high mixing efficiency, compact structure, stable operation, clean and environmental protection. Used in chemical, mining, ceramsite and other industries to humidify, mix and transport solid particles or powders.

Double Shaft Mixer Application Areas:

electric power, building materials, metallurgy, machinery, chemical and refractory materials industries.

Double Shaft Mixer Advantages :

The outstanding advantages of the Double Shaft Mixer are as follows:

1. The entire mixing and conveying process is carried out in a sealed space, no dust leakage, clean and environmentally friendly;

2. Integrate mixing, humidification and conveying, with good mixing uniformity, high production efficiency and large capacity;

3. The end of the shaft adopts labyrinth type and packing type combined sealing, which has double sealing effect and good sealing effect;

4. The mixing blade is made of wear-resistant material and has a special surface treatment, which has high wear resistance;

5. The double-shaft mixer has compact structure, small space occupation, stable transmission, high reliability and low noise.

Double Shaft Mixer Specifications:

| Model |

Mixing blade diameter |

Stirring shaft speed |

Production capacity |

Use helix angle |

Motor Power |

Equipped with reducer |

Stirring humidity (%) |

| ZJ300 |

450 |

50 |

10 ~ 20 |

12 ~ 21 |

11 |

JZQ400 |

15 |

| ZJ400 |

500 |

48 |

18 ~ 25 |

12 ~ 21 |

15 |

JZQ500 |

15 |

| ZJ500 |

550 |

45 |

20 ~ 30 |

12 ~ 21 |

18.5 |

JZQ500 |

15 |

| ZJ600 |

600 |

43 |

25 ~ 35 |

12 ~ 21 |

22 |

JZQ650 |

15 |

| ZJ650 |

650 |

41 |

28 ~ 42 |

12 ~ 21 |

30 |

JZQ650 |

15 |

Double Shaft Mixer Structure :

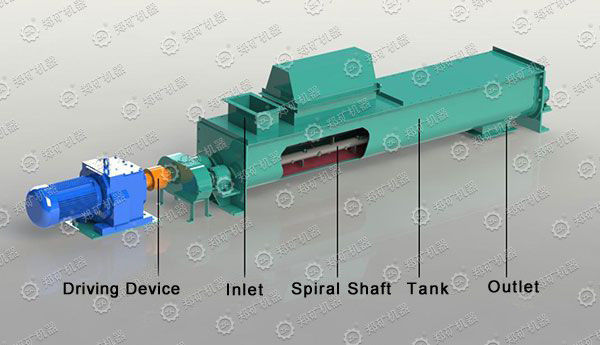

The main structure of the double-shaft mixer is mainly includes the driving device, the feed inlet screw shaft, the tank body, and the discharge port. The driving device is composed of motor-coupling-reducer-gear pair of the double-shaft mixer. The motor drives the reducer through the coupling, and then drives the gear pair to move to realize the opposite movement of the two spiral blade shafts. Spiral blades are installed on the spiral blade shaft, and the spiral blades are made of wear-resistant materials. The material enters the tank through the feed port, and is stirred and broken by the spiral blade. After the material has a uniform particle size, it is discharged from the discharge port.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!