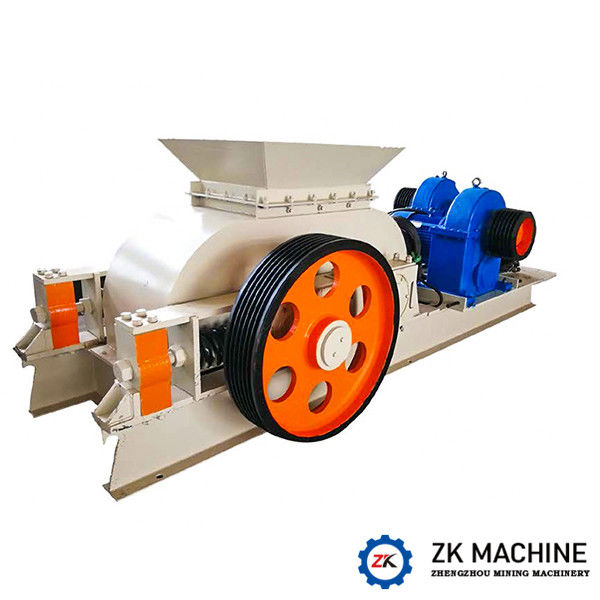

Double Toothed Roller Stone Crusher Machine 100T/H Large Production Capacity

Roll crusher is mainly used for secondary and fine crushing to materials below middle hardness, such as coking coal, clinker mineral, limestone, metallic and nonmetallic ore. Roll crusher is available for ore dressing, chemical, cement, refractories, abrasive, building materials industries, finely crushing all kinds of ore and rock below the high, medium hardness,which can make the minimum grain size below 100 mesh,especially in the building materials industry to produce melon meters stone and green bean products etc, and have the more excellent effect than general stave machinery , in recent years, also widely used in crushing steel grit industries.

Processing materials: various rocks, ores, limestone, construction waste, etc., used in the crushing of bulk materials in metallurgy, building materials, mining, highway, mineral processing and other industries

Application of Roller Crusher:

This series roller crusher is a crushing machine researched and manufactured by our company for coarse crushing. The roll crusher is widely used for crushing high hard and medium hard materials in such industrial departments such as metallurgy, building material and refractory. It has the features of low noise, little powder dust, reliable performance and convenient maintenance.Nowadays, many customers will first understand the technical parameters of the model of the double-toothed roller crusher before purchasing the double-toothed roller crusher to confirm whether it meets its own production requirements. Next, in order to help the processing enterprises to make better purchases, we will analyze the double-tooth roller crusher equipment with a production capacity of 100t/h.

The Principle of Double-tooth Roller Crusher:

The double-toothed roller crusher relies on the relative movement of the rollers, continuously presses and crushes the incoming materials, and the two rollers are fixed. The motor drives the roller shaft to rotate at a high speed through the belt. The two rollers are provided with a gap of 15-20 mm, and the block clay passes through two. The roller is extruded, and the extruded cake-like clay is discharged from the discharge port below the crusher, and hard materials such as stones can be directly discharged from the side discharge opening.

Features of Double Roller Crusher:

1. It's available for ore dressing, chemical, cement, refractories, abrasive, building materials industries;

2. Roll crusher has the more excellent effect than general stave machinery;

3. Finely crushing all kinds of ore and rock below the high, medium hardness,which can make the minimum grain size below 100 mesh;

4. Roller crusher is stable operation, easy maintenance, low cost, output size adjustable.

Parameter:

| Model |

Roller diameter

(mm)

|

Roller length

(mm)

|

Max inlet size

(mm)

|

Outlet granularity

(mm)

|

Rotation speed

of roller (r/min)

|

Production

capacity (t/h)

|

Power (kw) |

Weight

(t)

|

| 2PGφ400×250 |

400

|

250

|

32

|

2 ~ 8 |

200

|

20

|

11

|

1.3

|

| 2PGφ610×400 |

610

|

400

|

75

|

10 ~ 30 |

75

|

40

|

30

|

3.3

|

| 2PGφ750×500 |

750

|

500

|

40

|

2 ~ 10 |

50

|

60

|

30

|

12.25

|

| 2PGφ600×750 |

600

|

750

|

300

|

0 ~ 75 |

50

|

80

|

22

|

12.75

|

| 2PGφ900×900 |

900

|

900

|

600

|

0 ~ 100 |

37.5

|

125

|

30

|

13.27

|

|

2PGφ900×1200

|

900

|

1200

|

800

|

0 ~ 75

|

36

|

100

|

40

|

14.49

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!