description:

ZK has extensive expertise in the field of pelletizing and pelletizing technology, and the high-efficiency pelletizer can realize mixing and pelletizing in the same machine. The high-efficiency and clean granulator has a wide range of applications, such as ceramics, building materials, metallurgy, environmental protection engineering, etc. From small laboratory (8-15L) pelletizing to large industrial (φ1.5-1.9m) pelletizing, it can meet the needs.

Working principle of ceramic sand making machine:

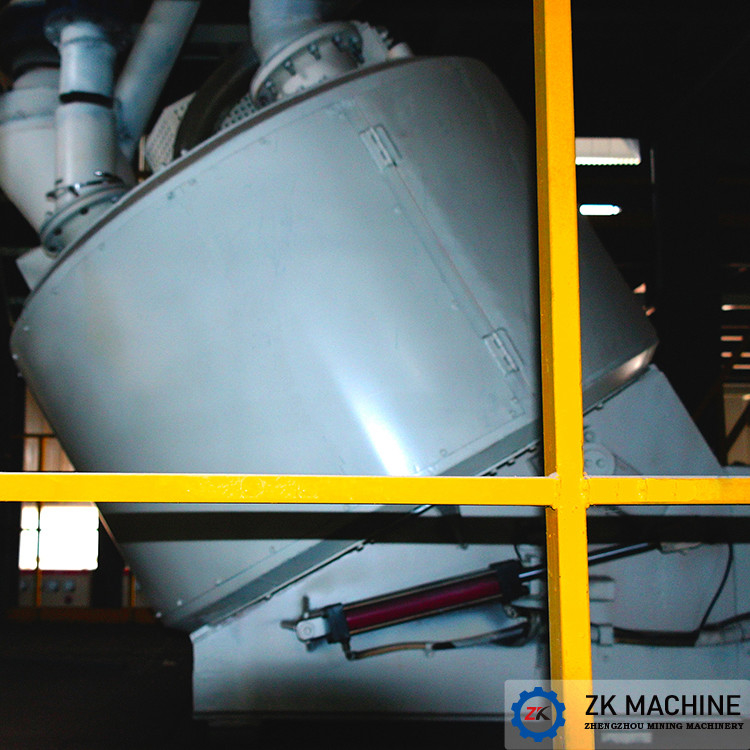

The working principle of ZKZL series clean and powerful granulator is to use the reverse motion between the low-speed clockwise rotating drum and the high-speed counterclockwise rotating rotor to stir the material at high speed. There are separate scrapers for the bottom of the drum and the wall of the drum. The scraper cleaning wall interacts with the inclined drum movement to form a special flow field and change the movement direction of the material. The powdered material is "rubbed" against the core during high-speed motion and then granulated into balls.

Advantages of our granulator:

1. The whole process of granulation is in a fully enclosed drum, and the inside of the drum is in a state of slight negative pressure. No dust pollution, clean and environmentally friendly.

2. Feeding-mixing-nucleation-granulation-shaping, the whole process is controlled by computer through PLC. Simple operation and high degree of automation;

3. The surface of the rotor is treated with wear-resisting and precise dynamic balance to ensure the stability, reliability and wear-resistance of the movement at high speed. Make the machine work stably and reliably, and maintain simple.

4. The scraper surface has been treated to resist wear. Wear-resistant linings are installed on the bottom and inside of the drum, so the entire drum component has a long service life and is cost-effective.

5. The unloading part of the drum is fully hydraulically driven. It has many advantages such as high degree of automation, simple operation and reliable drum sealing.

The main products of Henan Zhengzhou Mining Machinery Co., Ltd. are: ball mill, rotary kiln, vertical preheater, cooler, crusher, metallurgical oven, magnetic separator, flotation machine, classifier, feeder, bucket elevator , preheater, hoist, hoist, dryer and other dust collector related equipment. Metallurgy, cement, lime, mineral processing, refractory materials, chemical industry.

The products of Henan Zhengzhou Mining Machinery Co., Ltd. have been sold to all provinces of the country, and exported to Russia, South Korea, Vietnam, Malaysia, Nepal, Bangladesh, Mexico, Armenia, Africa, South America and other countries and regions.

Serve:

1 Professional organic granulation equipment manufacturing for 60 years, holding a variety of patented equipment and honorary qualifications.

2 The R&D team maintains continuous technological innovation, improvement and development, and has a team of innovative scientific and technological talents.

3 Strict quality control and whole process monitoring management.

4 ERP all-round pre-sale and after-sale service.

5 Free planning site design and installation basic drawings and flowcharts. One-on-one project team.

6 Have independent professional R&D capabilities, laboratories, and quality inspection capabilities.

Granulator Specifications:

| Type |

Max Capacity |

Power (kW) |

TTL Weight (t) |

| Weight (kg) |

Volum (L) |

| ZKZL-15 |

400 |

500 |

90 |

5 |

| ZKZL-16 |

500 |

600 |

110 |

6.5 |

| ZKZL-19 |

800 |

1000 |

132 |

10 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!