Product description

Hazardous waste solid waste rotary kiln mainly treats waste with one or more hazardous properties such as toxic, explosive, flammable and corrosive.Currently, there are two main ways to dispose of hazardous waste: incineration and landfill. Among them, the hazardous waste solid waste rotary kiln incineration technology is currently widely used hazardous waste treatment technology, and is becoming an important way for the harmless treatment of hazardous waste.

【Applicable materials】

Industrial comprehensive hazardous waste, medical waste, petroleum, chemical, pesticide and other industries of various solid waste, waste liquid, waste gas. Municipal domestic waste, etc.

Advantage

1.Low cost:high temperature material contacts refractory. Easy to change lining

2.The drive mechanism is simple: the drive mechanism is inside the kiln shell. Equipment maintenance is convenient.

3.To ensure no leakage of harmful gases: good sealing measures and negative pressure in the furnace.

4.Convenient operation and maintenance: high equipment operation rate. The annual operating rate is generally 90%

5.Incineration adaptability: solid waste, liquid, colloid and gas can be incinerated at the same time

6.High heat utilization rate: the material is stirred forward. Three heat transfer modes coexist in one furnace

7.Combined with patented technology: the traditional secondary combustion chamber has evolved into a secondary combustion furnace. Increases ash burn rate. Improve the combustion efficiency of the rotary kiln. At the same time, it has the functions of normal temperature slag discharge, slag breaking, air lock and so on.

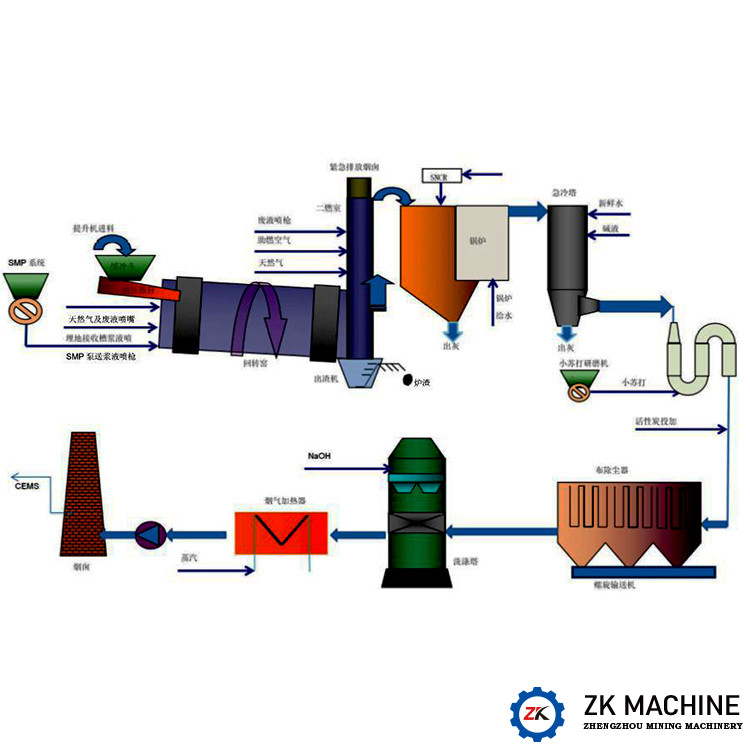

Process flow

Pretreatment feeding system - rotary kiln + secondary combustion chamber combustion system - waste heat recovery system - waste gas purification system - flue gas emission incineration system: including hopper, rotary kiln, secondary combustion chamber and combustion, fan, etc. Auxiliary equipment. Waste heat recovery system: including waste heat boiler and boiler auxiliary system equipment. Flue gas purification system: Cool the flue gas in the incinerator, remove harmful substances, and discharge it after meeting the emission requirements. Including quench tower, dust collector, scrubber, flue gas heater, activated carbon supply system, ash removal system, etc. Flue gas emission system: including induced draft fan, chimney, etc.

Specifications:

| Hazardous waste rotary kiln for waste incinerationφ2.6m*13.2 technical parameter. |

| Inner diameter of shell 2600mm |

Shell length 13200mm |

| Downstream arrangement, that is, the direction of material flow is consistent with the direction of smoke flow, the angle of the kiln body is 1.5 degrees. |

| Variable frequency speed control of rotary kiln |

0.1-2.2r/min |

| Drive mode |

Single side gear drive |

| Main Motor |

30kw |

| Kiln temperature:850-1200 degree |

Surface temperature of kiln shell: 180 degree |

| Expansion mode |

Linear free expansion at both ends |

| Total equipment weight |

approx. 54.5t |

| ★Customized waste incineration rotary kiln can be provided according to the customers' different industries |

Rotary Kiln Incinerator Working Principle:

Rotary Kiln Incinerator can deal with solid and liquid waste simultaneously, solid waste is sent into rotary kiln by special conveying equipment, liquid waste is sprayed into the feed end of the Rotary Kiln Incinerator body by means of an efficient atomizing device, the waste in the rotary kiln should experience the process of water evaporation, volatilization analysis, ignition and combustion process, The ash portion is discharged from the bottom of the second combustion chamber, the generated flue gas enters the second combustion chamber, blended with two combustion air in the second compartment, complete combustion of flue gas, achieve exhaust safety standards discharge.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!