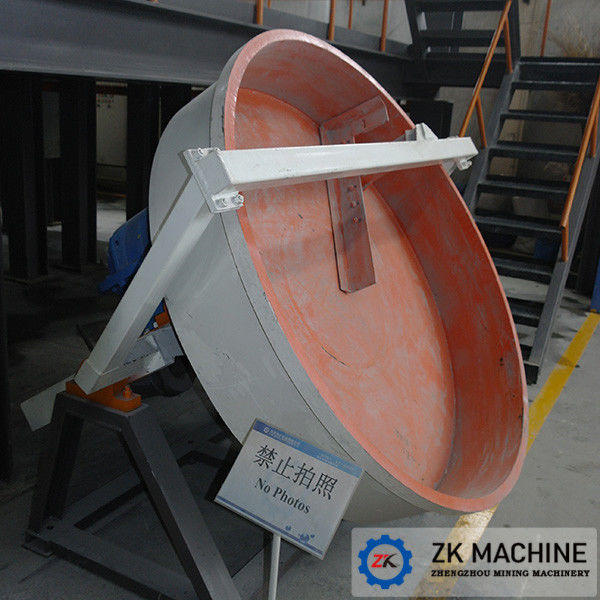

Modern High Efficiency Granulation Equipment 40 Tons Per Hour Powders Disk Granulator

Application of Disk Granulator:

Disc granulator is the main equipment for pelletizing powdery materials. It has the advantages of high pelletizing rate, high ball strength, stable operation, convenient control and long service life. It can be widely used in chemical, cement, steel, building materials and other industries.

Disk Granulator Includes the Following Structural Features:

The disc granulator produced by our ZK company is composed of disc body, transmission device, adjustable frame, scraper device, etc.

1. The bottom of the disc body is strengthened by a plurality of radiating steel plates, which has high strength and rigidity;

2. Transmission gear adopts high frequency quenching treatment, which has long service life;

3. The reducer and motor are driven by flexible belt, with stable starting, small impact force and overload protection;

4. The transmission system is equipped with a bridge device to reduce the direct impact between the gear and the reducer, and improve the operation stability of the equipment and the service life of the main parts;

5. The unique combination scraper device (disc bottom scraper and vertical scraper) is adopted to reduce the auxiliary power consumption.

The Working Principle of the Disk Granulator:

The disc body rotates around its center driven by the transmission device; when the powder is added to the pelletizing plate, the water spray device set above the pelletizing plate sprays water and humidifies it. Under the action of friction force, the wet powder continuously rolls and rotates in the disc, and gradually forms the mother ball, and the wet mother ball adheres to the ball, and the powder grows slowly, When the ball reaches the qualified size, it rolls to the edge of the disc and discharges itself under the action of centrifugal force and gravity.

Disk Granulator Specifications:

Unpowered scraper disc granulator technical parameters

| Type |

Disc Pelletizer |

Power(kW) |

| Dia (mm) |

Height(mm) |

Slope (°) |

Speed(r/min) |

| PQ10W |

1000 |

250 |

35-55 |

25 |

4.5 |

| PQ16W |

1600 |

300 |

35-55 |

19 |

4.5 |

| PQ22W |

2200 |

500 |

35-55 |

14 |

15 |

| PQ25W |

2500 |

500 |

35-55 |

14.25 |

15 |

| PQ28W |

2800 |

640 |

35-55 |

11.81 |

18.5 |

| PQ32W |

3200 |

640 |

40-50 |

9.06 |

22 |

| PQ36W |

3600 |

700 |

40-50 |

8 |

22 |

| PQ42W |

4200 |

800 |

40-50 |

7 |

30 |

Powered scraper disc granulator technical parameters

| Type |

Disc Pelletizer |

Main Power(kW) |

Weight(t) |

| Dia (mm) |

Height(mm) |

Slope (°) |

Speed(r/min) |

| PQ10 |

1000 |

250 |

35-55 |

25 |

4.5 |

1.8 |

| PQ16 |

1600 |

300 |

35-55 |

19 |

4.5 |

2.7 |

| PQ22 |

2200 |

500 |

35-55 |

14 |

15 |

3.9 |

| PQ25 |

2500 |

500 |

35-55 |

14.25 |

15 |

5.2 |

| PQ28 |

2800 |

640 |

35-55 |

11.81 |

18.5 |

5.7 |

| PQ32 |

3200 |

640 |

40-50 |

9.06 |

22 |

7.3 |

| PQ36 |

3600 |

700 |

40-50 |

8 |

22 |

8.6 |

| PQ42 |

4200 |

800 |

40-50 |

7 |

30 |

11.2

|

The Advantages of Our Disk Granulator are as Follows:

1. New structure, light weight, low height, flexible and convenient process layout;

2. It is convenient to adjust the angle of the ball forming plate;

3. The ball forming plate is composed of a disc body and a disc section. The disc section can be adjusted up and down along the disc body, and the end of the disc section is a side flange to ensure that the material ball will not be torn or torn when it comes out of the plate;

4. After the frame is welded and the stress is eliminated, the mating surface is processed on the boring and milling machine once to ensure higher assembly accuracy and more stable operation of the whole machine;

5. The combined scraper device can clean the bottom and edge, and match with the optimized pelletizing plate, which makes the pelletizing effect better, and the qualified pellets can reach more than 90%.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!