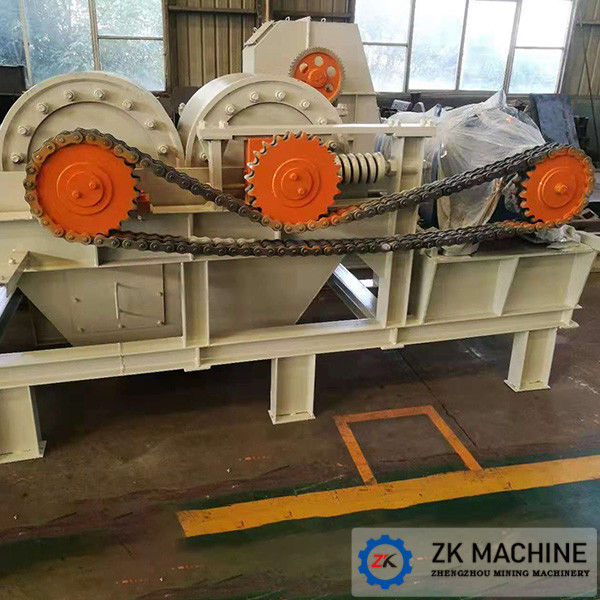

Used In Small Particle Material Double Roller Granulator Long Service Life

Double Roller Granulator Introduction:

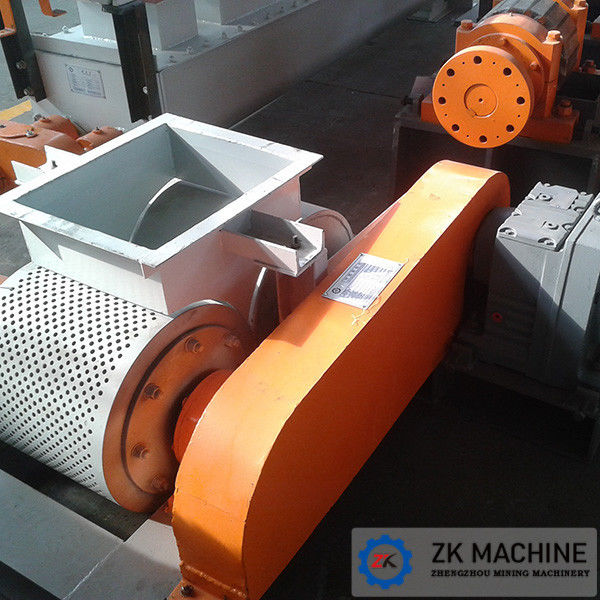

The Double Roller Granulator, as the name suggests, is a device for granulating through pairs of rollers, which is widely used in the ceramsite industry. The "roller" here refers to a cylindrical roller. Unlike the steel mill roll, the roller of the counter-roll granulator is hollow and is called a "roll skin".

According to the requirements of materials and output, the Double Roller Granulator can adopt two-roll perforated roll skin and single-roll perforated roll skin. Both have their advantages and disadvantages. Among them, the double-roll perforated roll skin is more efficient. The single roll with holes has higher granulation strength. If a single-roller with holes is used, the material enters the double-roll granulator, and the rolls are squeezed into each other, enter and pass through the circular holes distributed on the roll, enter the inside of the bracket, and are discharged from the end surface of the opposite roll to complete the process. grain. The roller granulator is used in the ceramsite industry. The conventional hole diameter is 12-15mm, and the minimum hole diameter is generally considered to be 8mm. Rolls with a hole diameter of less than 8mm are difficult to process and frequently block the granulating holes; 20-25mm, can also be thickened according to requirements.

Therefore, the roller skin, as an important vulnerable part of the roller granulator, is in direct contact with the material and participates in the whole process of granulation. It is affected by the friction between the roller skin and the roller skin, the reaction force of the material in the crushing process, and the material passes through the roller. As time goes by, the friction force of the skin, such as the thickness of the roller skin becomes thinner, the diameter of the hole expands, and the granulation holes are blocked by metal, which affects the granulation efficiency, the strength of the pellets, and the increase of scrap and burrs. At this time, the roller belt needs to be replaced.

The roller skin is installed on the fixed roller and the movable roller. The roller skin and the bracket are installed separately and fixed by bolts, which can be easily disassembled and replaced.

Advantages of Disc Granulator:

This type of equipment has simple structure, light weight, flexible and convenient process layout; it can control the particle size and output of the ball by adjusting the inclination angle of the ball disc, the motor speed and the amount of water spray.

Double Roller Granulator Specifications:

| Model |

Roller |

Motor Power(kW) |

Capacity(t/h) |

|

Diameter

(mm)

|

Length

(mm)

|

Rotating Speed (r/min) |

| DG3530 |

φ350 |

300 |

58 |

5.5 |

1 |

| DG4035 |

φ400 |

350 |

58 |

7.5 |

1-2 |

| DG4540 |

φ450 |

400 |

58 |

11 |

2-3 |

| DG5045 |

φ500 |

450 |

58 |

15 |

3-4 |

| DG6055 |

φ600 |

550 |

65 |

18.5 |

5-6 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!