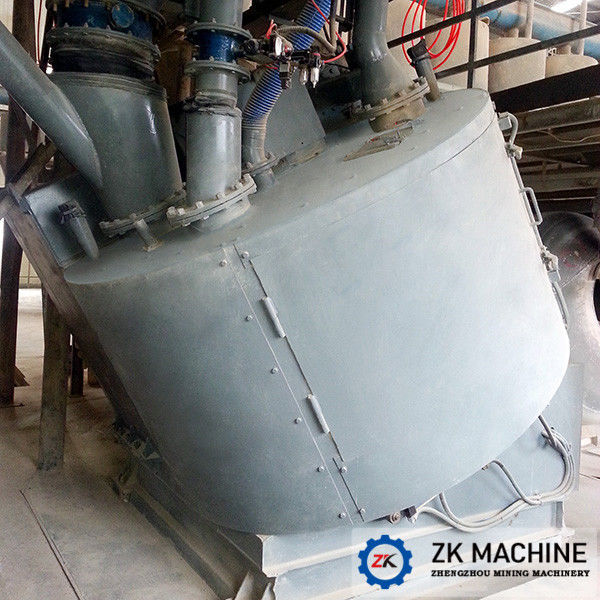

Ceramic Sand Granulator Reliable Performance Large Capacity From Manufacturer

Ceramic Sand Granulator Introduction:

Ceramic sand granulator is designed on the base of learning foreign advanced technology and studying domestic oil fracturing proppant production status. It is mainly used for production of oil fracturing proppant (ceramic sand), and also be applied for balling powder, granular, small lump material such as coal powder, limestone, coal, clay and etc.

Ceramsite has the characteristics of light volume density, loose and porous inside, low thermal conductivity, etc., at present, it has become one of the main raw materials of building material blocks. Among the raw materials of ceramsite, sludge is also one of the main raw materials, and the proportion of sludge ingredients is about 10-30%.

Ceramsite can be divided into: shale ceramsite, clay ceramsite, coal gangue ceramsite, etc. The main raw materials of shale ceramsite are shale and sludge. Shale ceramsite system can be divided into: shale crushing, drying, grinding, batching, aging, granulation, firing, cooling, and finished product conveying system.

Henan Zhengzhou Mining Machinery Co., Ltd. is devoted to the research of the sludge ceramsite industry and the equipment manufacturing in line with the tenet of "Virtue in advance, benefit after people". It is a company that integrates equipment manufacturing and process design. Through the supply, design and debugging experience of multiple actual ceramsite production lines, we can provide customers with high-quality mechanical equipment and mature process technology services.

Our Advantages:

It is mainly used for production of oil fracturing proppant (ceramic sand), and also be applied for balling powder, granular, small lump material such as coal powder, limestone, coal, clay and etc.

1. The whole process of granulation is inside the fully enclosed drum, and the drum interior is at slightly negative pressure state. It is without dust pollution, clean and environmental friendly.

2. Feed - mixing - nucleation - granulators - shaping,the whole process is controlled by computer through PLC. It is easy operation and high degree of automation;

3. After abrasion treatment, the rotor surface had made precise balancing to ensure movement stability, reliability and wear resistance under high rotational speed. So that the machine can work stable and reliable;

4. The scraper surface has had appropriate wear treatment. The bottom and the inside of the drum is equipped with wear-resistant liner, therefore, the entire drum parts have a long service life.

Specifications:

| Specification |

ZK-15 Granulator |

Diameter 1.2m

Disk Granulator

|

Diameter 1.7m

Disk Granulator

|

Diameter 2.5m

Disk Granulator

|

Diameter 3.2m

Disk Granulator

|

Diameter 3.5m

Disk Granulator

|

Diameter 4.2m

Disk Granulator

|

| |

1 |

4 |

1 |

50 |

1 |

20 |

1 |

12 |

1 |

6 |

1 |

4 |

1 |

3 |

| Capacity (t/h) |

2.5 |

10 |

0.2 |

10 |

0.5 |

10 |

1 |

10 |

2.5 |

10 |

2.8 |

10 |

3.5 |

10 |

| Working System(h) |

24 |

24 |

24 |

24 |

24 |

24 |

24 |

24 |

24 |

24 |

24 |

24 |

24 |

24 |

|

Annual Working Days

(d)

|

300 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

| Annual Capacity(T/A) |

18000 |

72000 |

1440 |

72000 |

3600 |

72000 |

7200 |

86400 |

18000 |

72000 |

20160 |

72000 |

25200 |

72000 |

| Power(kW) |

90 |

360 |

11 |

550 |

15 |

300 |

45 |

540 |

75 |

450 |

75 |

300 |

90 |

270 |

|

Electric Consumption

( kW/t)

|

36 |

36 |

55 |

55 |

30 |

30 |

45 |

45 |

30 |

30 |

25 |

25 |

25.8 |

25.8 |

| Coverage(m2) |

25 |

100 |

9 |

450 |

16 |

320 |

18 |

216 |

32 |

192 |

32 |

128 |

40 |

120 |

|

Product Size

(mesh)

|

16/80 |

16/80 |

16/80 |

16/80 |

16/80 |

16/80 |

16/80 |

16/80 |

16/80 |

16/80 |

16/80 |

16/80 |

16/80 |

16/80 |

|

Human Resource

(People)

|

|

3 |

|

50 |

|

27 |

|

24 |

|

16 |

|

12 |

|

9 |

|

Product Market Price

(RMB/t)

|

3800 |

2800 |

2800 |

2800 |

2800 |

2800 |

2800 |

|

Equipment Investment

(ten thousand RMB)

|

40 |

160 |

2.5 |

125 |

7 |

140 |

12 |

144 |

18 |

72 |

22 |

|

28 |

84 |

| More Plant Area(m2) |

|

350 |

220 |

116 |

92 |

28 |

20 |

|

Workers Annual Salary

(ten thousand RMB)

|

10.8 |

180 |

97.2 |

86.4 |

46.8 |

32.4 |

21.6 |

| Pollution |

no |

serious |

serious |

serious |

serious |

serious |

serious |

| Automation |

Total Automation |

Manual Work |

Manual Work |

Manual Work |

Manual Work |

Manual Work |

Manual Work |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!