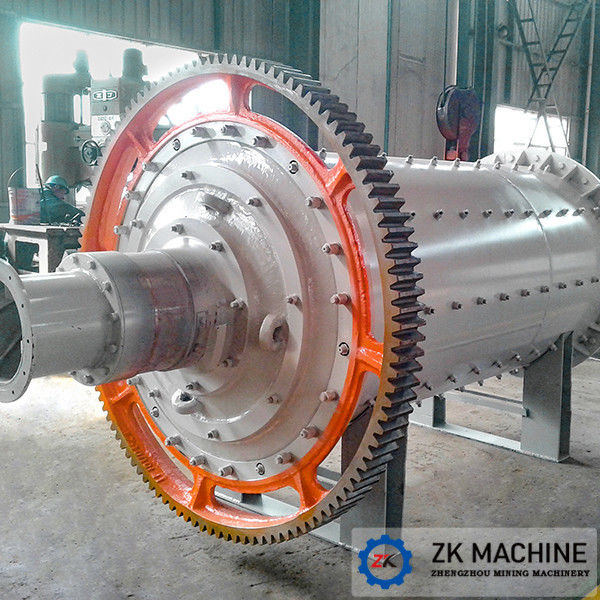

900*900 Horizontal Ball Mill Widely Used Highly Efficient Large Capacity

Horizontal Ball Mill Introduction:

Horizontal Ball Mill is widely used in cement, silicate products, new building materials, refractory materials, fertilizer, ore dressing of black and nonferrous metals and glass ceramic production industry, for dry and wet powder grinding various ores and other grinding materials.

Application Fields:

Cement, coal, power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

Applicable Materials:

Limestone, calcite, barite, dolomite, potassium feldspar, marble, talcum, gypsum, kaolin, bentonite, medical stone, rock phosphate, manganese ore, iron ore, copper ore, gold ore, quartz, active carbon, carbon black, ceramic, coal, etc.

The Outstanding Advantages of Ball Mills:

1. Maintain the uniform and continuous delivery of materials to the ball mill to ensure that the equipment is constantly feeding and not blocking;

2. The ball mill using steel balls as the grinding medium can appropriately increase the grinding area or increase the number of steel balls to increase the output;

3. Add grinding aids in the mill to effectively improve its production capacity;

4. It adopts high-quality motor as its core component, so it has greater production capacity and higher working efficiency, so the output can also meet user standards.

5. The failure rate is almost zero. Some customers report that there is no process failure within two years of work, so it can successfully complete the task.

Specifications:

| Model |

Rotary speed (r/min) |

Ball loading(t ) |

Feed size (mm) |

Discharging size (mm) |

Output capacity (t/h) |

Motor power (kw) |

Weight (t) |

| 900*900 |

40 |

0.67 |

0-20 |

0.074-0.6 |

0.23-0.74 |

15 |

4.5 |

| 900*1800 |

38 |

1.5 |

0-15 |

0.075-0.8 |

0.3-0.8 |

y11- 4 |

3.8 |

| 900*2100 |

38 |

2.0 |

0-15 |

0.075-0.8 |

0.5-1.3 |

y15-4 |

5.6 |

| 900*3000 |

36 |

2.7 |

0-20 |

0.075-0.8 |

1.1-3.5 |

22 |

|

| 1200*2400 |

36 |

3 |

0-20 |

0.075-0.6 |

1.5-4.8 |

30 |

12 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!