Introduction of Ore Beneficiation Line:

Henan Zhengzhou Mining Machinery Co., Ltd has been committed to providing customers with more professional overall beneficiation services, from beneficiation consultation, beneficiation testing to beneficiation plant design, beneficiation equipment production, to beneficiation plant equipment installation and commissioning, to achieve standard production, complete metal and non-metallic beneficiation projects, and continuously improve and optimize their own services to form their own service system, starting from every detail, for customers in all aspects.

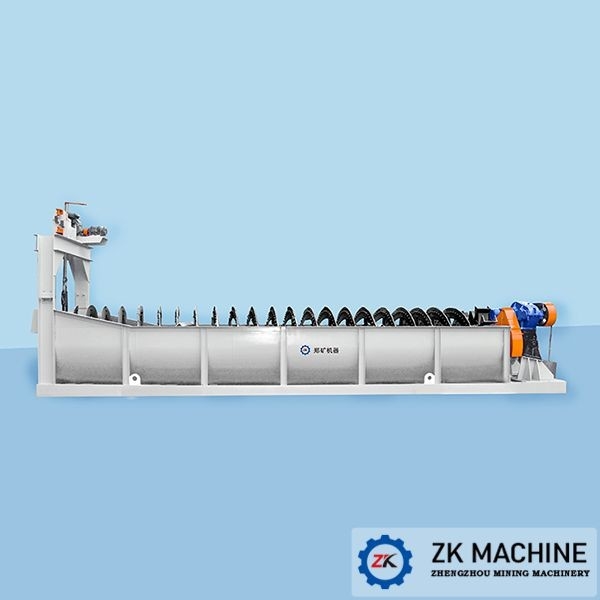

The beneficiation production line is mainly composed of jaw crushers, ball mills, classifiers, magnetic separators, flotation machines, thickeners and dryers, supplemented by feeders, elevators and conveyors. This production line has the advantages of low energy consumption, high output and economic rationality.

Capacity: 10,000-300,000 tons/year

Main equipment: ball mills, crushers, flotation machines

Service scope: Provide overall solutions and equipment for beneficiation lines

Advantages of Ore Beneficiation Line:

1. It has the advantages of low energy consumption, high output and reasonable economy.

2. The process is simple, the cost of mineral processing equipment is low and easy to operate.

3. It provides customers with more professional overall mineral processing plant services, from mineral processing consultation, mineral processing tests to mineral processing plant design, mineral processing equipment production, and then to mineral processing plant equipment installation and commissioning, to achieve standard and production, and complete metal and non-metal mineral processing projects.

Production Process of Ore Beneficiation Line:

The ore is first sent to the jaw crusher for primary crushing, and then the ore will be sent to the ball mill for fine crushing and grinding to the appropriate size. The ore powder discharged from the ball mill will be sent to the next process: screening. Due to different specific gravities and sedimentation rates, the spiral classifier can clean and group the ore mixture. The clean and grouped ore mixture is sent to the magnetic separator. Due to different magnetic susceptibility coefficients, the magnetic material will be separated from the mixture under the action of magnetic and mechanical forces. Then the mixture is sent to the flotation machine. According to the characteristics of different ores, we add different additives to the mixture to separate the ore we want to get from the mixture. After the mixture is separated, the ore we get always contains a lot of water. We need to use a concentrator to concentrate it first and then use a dryer to dry it, and then we can get dry ore.

Overview of Our Factory:

Henan Zhengzhou Mining Machinery Co., Ltd. is a manufacturer specializing in mining equipment. The company commits to providing innovative technologies and tailored product solutions for mining and energy sectors in many countries and regions worldwide. After years of development, it becomes a comprehensive modernized enterprise, which covers a land area of 80,000 ㎡, a workshop area of exceeding 60 000㎡ and an office area of more than 5000 ㎡. Now ZK owns 6 modernized workshops, 5 heavy equipment workshops, and 1 Zhengzhou municipal level Research & Development center, including various of large & medium machining, rivet welding, assembling equipment, which are over 300 sets. Backed by net assets of 200 million RMB, we offer integrated services, including scientific research, design, develop, manufacture, sales, installation, test and training.

Main products include: Feeder, Crusher, Vibrating Screen, Ball Mill, Spiral Classifier, Flotation Machine, Gravity Separation Equipment, Rotary Kiln, Cooler, Dust Collector, Conveying equipment and so on, and other complete set of mechanical equipment used in Metallurgy, Cement & Building materials, Lime, Ore dressing, Refractory, Chemical industries and so on. The products of company sold to each province very well in China, and sold to more than 100 countries and areas, such as Japan, British, Saudi, Turkey, Pakistan, Thailand, Russia, South Korea, Vietnam, Malaysia, Nepal, Bangladesh, Armenia, Iran, Guatemala, India, Mongolia, Africa, South America, and we have received good reputation from clients.

ZK insists on the quality policy "Survive on quality, develop on technology". Now ZK has got ISO9001:2008 Quality Management System Certification, ISO14001:2004 Environment Management System Certification and OHSAS18001:2007 Occupational Health & Safety Management System. ZK has got 3 patents for invention and more than 20 patents for utility models. And ZK has been awarded "Henan New High-tech Enterprise", "Zhengzhou Top 100 Private Company", "High Quality Products of Henan Province","Famous Brand of Henan Province", "Zhengzhou Ecommerce Pioneer Company", "Zhengzhou City Enterprise Technical Center", etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!