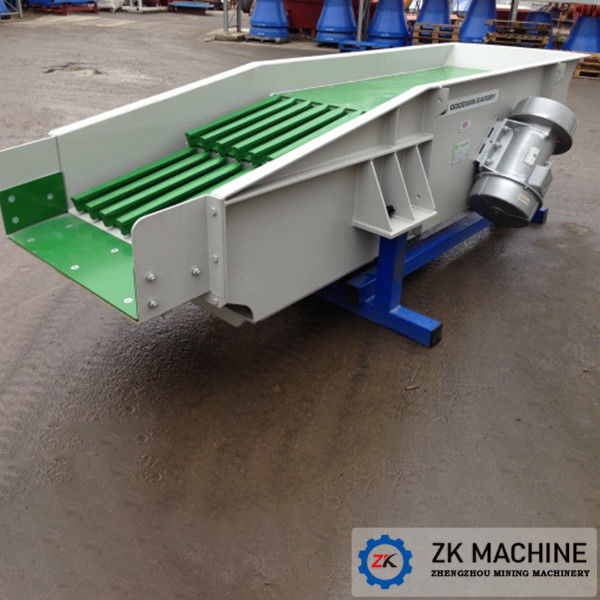

Vibrating Feeder / Grizzly Feeders for Sale in All Over the World

Vibrating Feeder Introduction:

Vibration Grizzly Feeder series are widely used in mining, metallurgy, construction, light industry, electricity, food and other industries. It can transport the material with the shape like cubic and granularity into the receiving device continuously and timely with the stable speed in the production line.

Our Advantage:

1. Advanced vibration mechanism with low energy consumption because of working on low critical near resonance state;

2. Adopt Silicon controlled rectifier half-wave rectifier control method, when operating, automatic control can be realized by adjust the development angle of silicon controlled.

3. Due to the instantaneous change or opening and closing for material flow, the feeding volume with high accuracy.

4. When operating, material will been throw up continuous, then jumping forward with parabolic trajectory, so that have less abrasion to screen cell.

5. Widely application, alloy screen cell feeder can used for conveying wear and corrosive materials, sealing structure feeder can used for high pollution and easy to dust material.

6. Feeder with features like small overall size, light weight, simple structure, no need lubrication and easy to maintenance.

Structure of Construction Vibration Grizzly Feeder:

Vibrating grizzly feeder consists of vibrating frame, spring, vibrator, motor vibrating device and motor. The vibrator is made of two fixed eccentric shafts whose gears are jogged. When installation, the two gears must be jogged according to the sign. Through drive of the motor, the two eccentric shafts start rotating to produce a linear huge power which forces the feeder to vibrate. Through the vibration, the materials will slip and sling on the funnel, moving forward, when the materials pass the screening part, smaller parts will fall down, avoiding the further crushing, so screening purpose can be reached.

Metallurgy Vibration Grizzly Feeder Our Advantage:

1. Vibrating grizzly feeder adopts imported manufacturing technology in Finland, Sweden, frame type ring vibrator Kai rivet connection structure, firm structure, high strength, wear resistance.

2. Vibrating grizzly feeder using manganese steel plate and bar with enough rigidity, can withstand the impact of large stone.

3. Vibrating grizzly feeder discharge side has special bar structure, the gap can be adjusted at the same time, give full play to the effect of back breaking machine.

Mining Vibration Grizzly Feeder Specifications:

| model |

max feed size(mm) |

Capacity(t/h) |

Motorpower(kw) |

Slop(°) |

| GZT-0724 |

450 |

30-80 |

2×1.5 |

10 |

| GZT-0932 |

560 |

80-150 |

2×2.4 |

10 |

| GZT-0940 |

560 |

180-180 |

2×3.2 |

10 |

| GZT-1148 |

600 |

150-300 |

2×5.5 |

10 |

| GZT-1256 |

800 |

180-400 |

2×7.5 |

10 |

| GZT-1560 |

1000 |

400-600 |

2×1 |

10 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!